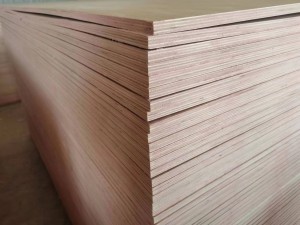

Okoume Marine Plywood sheet 4ftx8ft

products Specification

| Product name | Okoume marine plywood |

| After sale service | Online technical support |

| Project solution capability | Total solution for projects |

| Design style | Modern or as your requirements |

| Place of origin | Shandong, China |

| Grade | First -class |

| Formaldehyde Emission Standards | E0 |

| Veneer Board Surface Finishing | Double-sided decoration |

| Face/back | F:Okoume or as your request |

| Core | C:Poplar, Eucalyptus, Birch, Combi, etc |

| Size | 1220x2440mm/1250x2550mm/as Request |

| Thickness | 4mm, 6mm, 9mm, 12mm.15mm, 18mm,21mm, 25mm.28mm etc |

| Glue | E0, E1, E2, MR, WP, Melamine |

| Density | 500-700kgs /M3 |

| Color |

Solid color, wood grain, marble grain, cloth grain etc We have melamine paper atlas,We have thousands of different color styles. We can provide customized service to produce the same color according to customer's samples |

| Moisture | 8-14% |

| Water absorption | <10% |

| Certification | CE ,FSC ,CARB ,EPA |

| Application | Home decoration, panel furniture, cabinet wardrobe, bathroom cabinet and other fields. |

Property

Marine plywood is plywood made with durable faces and core veneers with few defects so it performs well under wet conditions.

Originally invented for the manufacture of boats and yachts, marine plywood now is increasingly used in construction work where the durability of plywood is required.

Marine plywood has a low formaldehyde emission level thanks to the high-quality phenolic glue used.

The use of durable veneers and phenolic glue means that marine plywood offers a higher level of resistance to wet conditions.

In some ways it would make most sense for the plywood is suitable for boat building to be the only plywood with a marine grade level. And this is not so. Water resistance, bending ability, and appearance are all key. The marine plywood is either expected to be a show face or at least a consistent face that can operate as a reliable surface for a decking veneer . loading press is another factor to consider but it depends upon your specific construction needs.As far as water resistance, marine plywood in accordance with BS1088 should be ensure the long term durability.