Types of film faced marine plywood

Poplar film faced marine plywood or construction formwork

Eucalyptus film faced marine plywood or construction formwork

Pine film faced marine plywood or construction formwork.

The price is also higher for eucalyptus than for poplar, and for birch than for eucalyptus. The usage cycle of birch wood is also long, and the concrete produced on the surface has a high flatness. If it is to build ordinary commercial housing, poplar marine plywood can be used because of their low cost and no need for repeated turnover, which can meet the usage needs. If it is to build a high standard highway or bridge project, birch marine plywood need to be used because the overall cost is low, and the concrete produced does not require secondary treatment and is very smooth.

Types core of film faced plywood

whole core film faced marine plywood ,

Finger joint core film faced marine plywood

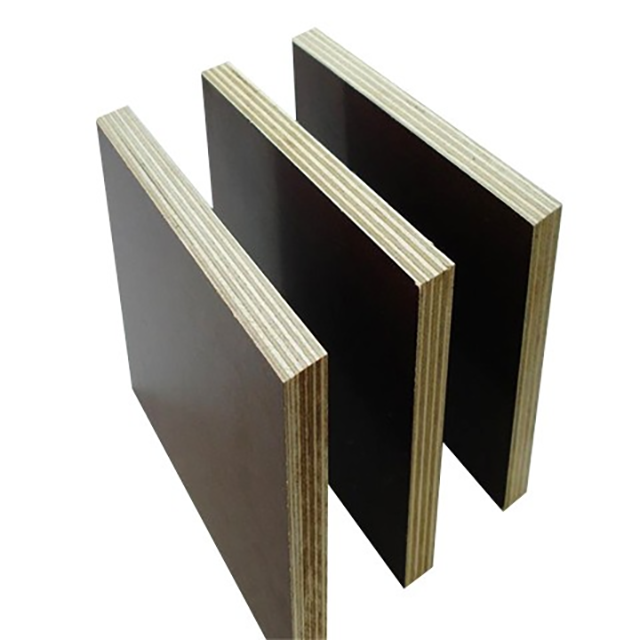

The detail information of the whole core film faced marine plywood

Face and back paper: brown film with logo; Black filmwith logo–

Core : poplar core, Eucalyptus core or combi core

Glue: WBP ,MR ,or as your requirements

Size: 1220x2440mm; 1250x2500mm

Thickness: 9mm, 12mm; 15mm; 18mm; 21mm—

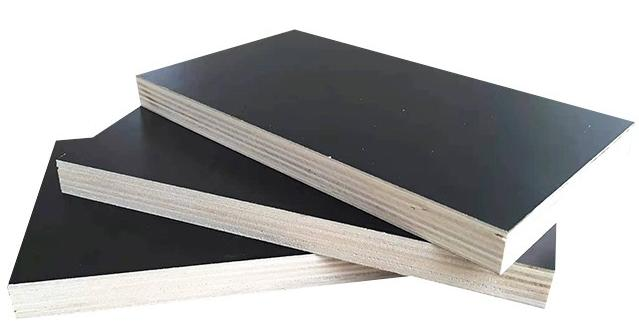

The detail information of finger joint core film faced marine plywood

Face and back paper: brown film with logo; Black filmwith logo –

Core : finger jiont core

Glue: WBP ,MR ,or as your requirements

Size: 1220x2440mm,1250x2500mm

Thickness: 9mm, 12mm; 15mm; 18mm; 21mm—

The main advantages of film faced marine plywood

1.)Lightweight: More suitable for high-rise building and bridge construction.

No warping, deformation, cracking, good water resistance, no glue opening after 24 hours of boiling, good strength performance, high turnover times, and long service life. It is easy to remove the film .

2.)Making plain concrete: The surface of the poured object is smooth and beautiful, minus the secondary wall plastering process, it can be directly applied for decoration. Reduce the construction period by 30%.

3.)Corrosion resistance: does not pollute the concrete surface.

4.)Good insulation performance, beneficial for winter construction.

5.)Good construction performance, superior to bamboo plywood and small steel plates in terms of nail, saw, and drilling performance. It can be processed into various shapes of membrane boards according to construction requirements.

The difference between primary and secondary molding of marine plywood for construction

1. )The production of product processes varies

The so-called primary and secondary molding refers to the number of times a marine plywood passes through a hot press. One time molding is a marine plywood that is directly formed after only one hot press. Second time molding is the process of first forming the substrate, then sanding, polishing, ,puttying, then applying film paper, and then entering the hot press to apply the film, which is the process of two hot presses.

2. )The smoothness, flatness, and brightness of the product are different

From the surface of the formwork plywood , it can be intuitively seen that the brightness and flatness of the first molding are much worse than those of the second molding, and there are generally pits on the surface, which is caused by the gaps placed between the layers.

3.)Different bonding forces of products

The secondary formed marine plywood has undergone two rounds of hot pressing, and its bonding force is much greater than that of the primary formed marine plywood. Moreover, it is super flat, smooth, and waterproof. Boiling water usually takes more than 2 hours, and without opening the adhesive, it will not peel. However, the boiling time of ordinary one-time molding templates cannot meet this standard. If you want to build high-quality buildings or carry out construction in humid and rainy Jiangnan areas, it is generally recommended to use secondary formed building templates with good waterproof properties.

4. )Different product usage times

The use of secondary molding marine plywood is 4-5 times higher than that of regular primary molding marine plywood. There are even more than 10 times differences.

5.) Differences in product cost and cost-effectiveness

Due to the complexity of the production process, the same labor force, and the same time, the production quantity of secondary molding is lower than that of primary molding board. So the secondary moulding cost is higher .

How to choose film faced marine plywood

1. )Appearance

A high-quality construction formwork plywood also has a natural and beautiful texture. Generally, due to a layer of paint on the surface of the plywood, we cannot see its internal defects with the naked eye. Therefore, we need to use our hands to check as long as the plywood feels smooth and flat.

2. )Material

We have learned from the previous text that there are many materials for construction marine plyywood, so we need to choose materials and specifications that match the building. If the selected marine plywood do not match, it will affect construction efficiency.

3.) Turnover Times

Building marine plywood that can be used multiple times. If the bearing capacity of building marine plywood is strong, the turnover times will be relatively high.

Note:

1.)The edges have been sealed before leaving the factory. After cutting or drilling, please apply water resistant phenolic series paint to the sawn edges or holes seven or three times at intervals. If there are scratches or bruises, phenolic resin should be repainted.

2.)Before use, a layer of release agent should be evenly applied to the surface to facilitate demolding and surface cleaning, which directly affects the quality of the concrete surface. Correct use can extend the lifespan of the template.

3.)After the template is removed, please clean it immediately with non-metallic tools such as brushes and soft scrapers. When storing, the edges and corners should be aligned and stacked on a flat ground. There should be partitions on the bottom layer, do not come into contact with the ground, and have good ventilation. At the same time, prevent sunlight and rain, and conduct regular inspections.

Post time: Nov-02-2023