shandong birch faced plywood 3-35mm poplar/eucalyptus core plywood for furniture/construction

products Specification

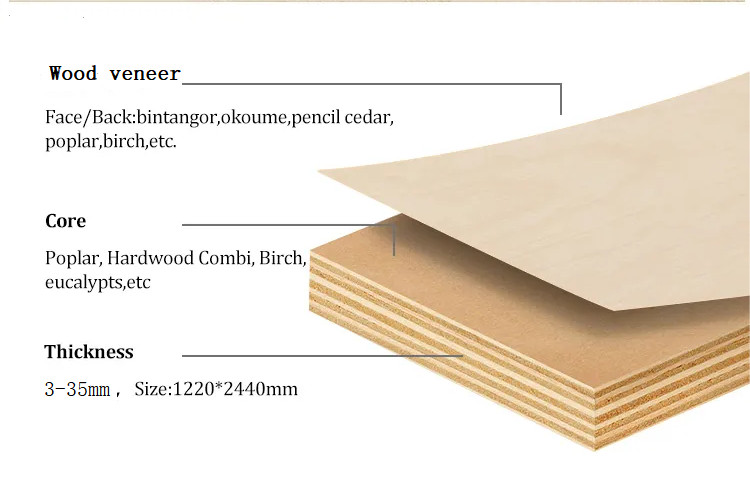

| Product name | Birch commercial plywood for furniture |

| Formaldehyde Emission Standards | E0 |

| Veneer Board Surface Finishing | Double-Sided Decoration |

| Veneer Board Surface Material | Wood veneer |

| Face/Back: | Birch |

| Core: | Poplar, Hardwood, Combi,etc |

| Standard sizes: | 1220×2440mm, 1250×2500mm or as your request |

| Standard thicknes: | 3-35mm |

| Glue: | E0, E1, E2, MR, WBP, Melamine |

| Grading: | BB/BB, BB/CC, DBB/CC |

| Moisture content: | 8%-14% |

| Water absorption | <10% |

| Density: | 550-700kg/M3 |

| Thickness Tolerance: | below 6mm: +/_0.2mm; 6mm-30mm: +/_0.5mm |

| Application: | Furniture ,cabinets ,other appliance decoration |

| Package | bottom is wood pallet, around is carton box , strength by steel tapes 4*6. |

Features

1. Smooth surface: When used, the surface is smooth, with high flatness, no carbonization, and the overall thickness of the board is uniform.

2. Good adhesion: During production, melamine waterproof adhesive and phenolic adhesive are used for bonding, ensuring the bonding strength.

3. Has good water resistance: Even if soaked in water for a long time, nothing will happen.

4. Excellent internal core material: When producing all birch plywood, each board is screened and repaired before use, and the bonding strength is good after production. It has advantages such as non opening, non fracture, waterproof, and anti-corrosion, and has obvious advantages in use.

Write your message here and send it to us