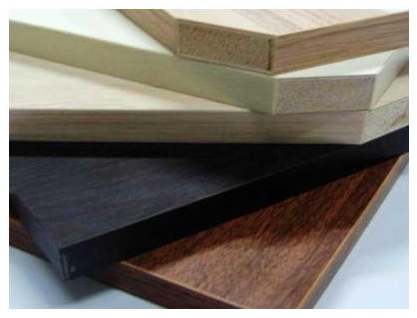

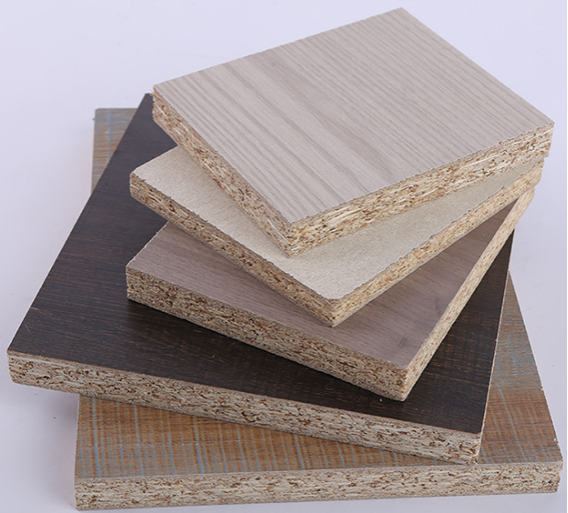

Melamine faced boards are made of particle board, MDF, block board and plywood which are bonded together with the surface. The surface veneers are mainly domestic and imported melamine . Due to their fire resistance, wear resistance, and waterproof soaking treatment, the use effect is similar to that of composite wood flooring.

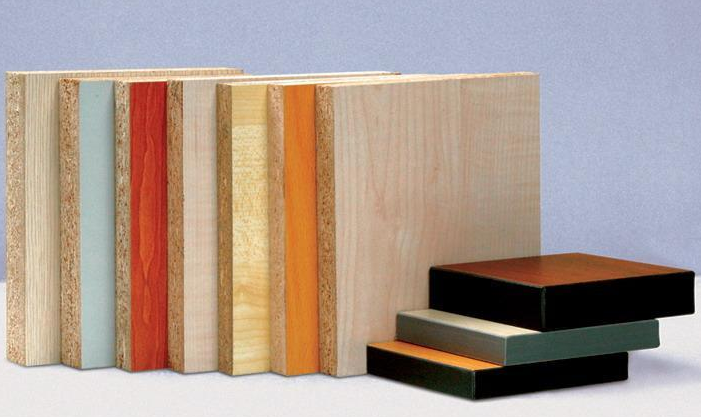

Melamine board which is a synthetic board with melamine impregnated adhesive film paper veneer. It is a decorative board made by soaking paper with different colors or textures in melamine resin adhesive, drying it to a certain degree of curing, and laying it on the surface of particle board, medium density fiberboard, plywood, blockboard, multi-layer board, or other hard fiberboard, after hot pressing. In the production process, it is usually composed of several layers of paper, and the quantity depends on the purpose.

Soak the decorative paper in a melamine solution and then press it onto it through hot pressing. So, the moisture-proof board used for furniture is generally called melamine moisture-proof board. Melamine formaldehyde resin is a solution with extremely low formaldehyde content, which is environmentally friendly. This way of sticking it on not only does not cause secondary pollution, but also reduces the release of the substrate inside. This treatment method has been recognized by many people and is mostly done in this way.

The commonly used processing process for melamine veneers is the hot pressing process. However, it should be noted that during the hot pressing treatment, there are three processing factors that will affect its final effect. These three factors are the time of hot pressing, the temperature of hot pressing, and the appropriate pressure.

Three Elements of Hot Pressing Process for Melamine Paper

Hot pressing time: Its length depends on the curing rate and hot pressing temperature of the melamine resin, usually within 40-50 seconds. Long time can cause excessive resin curing, loss of elasticity, and easily cause cracks or internal stress in the product, resulting in cracks and warping during subsequent processing. If the time is too short and the resin curing is not sufficient, it is easy to produce adhesive board phenomenon, and it affects the physical and chemical functions of the product surface, affecting the durability of the product.

Hot pressing temperature: mainly plays a catalytic role in the chemical reaction of melamine resin, i.e. accelerates curing. According to the actual production requirements and the author’s experience, the temperature of the hot pressed plate is more suitable at 145-165 ℃. High temperature helps with demolding after pressing, and can shorten the hot pressing period and increase production. However, excessive temperature prevents the resin from uniformly flowing and solidifying, resulting in small pores on the board surface.

Appropriate pressure: It can ensure a good combination between the substrate and melamine paper. Under the action of appropriate temperature and pressure, the resin in melamine paper melts and solidifies, forming a closed and dense surface. It can also fill the unstable small pores on the substrate surface. When the pressure is generally 2.0-3.0MPa, it is recommended to use a low pressure as much as possible without affecting product quality, which is beneficial for the service life of equipment, hydraulic oil, and the internal structure of the substrate. But too low pressure affects the bonding strength and resin flow ability between the substrate and melamine paper.

Composition:

Melamine “is one of the resin adhesives used to manufacture this type of board. Paper with different colors or textures is soaked in the resin, dried to a certain degree of curing, and then laid on the surface of particle board, medium density fiberboard ,block board and plywood. It is a decorative board made by hot pressing, and the standard name is melamine impregnated adhesive film paper veneer artificial board, Calling its melamine board is actually a part of its decorative composition. It is generally composed of surface paper, decorative paper, covering paper, and bottom paper.

1.)Surface paper is placed on the top layer of the decorative board to protect the decorative paper, making the surface of the board highly transparent after heating and pressure. The board surface is hard and wear-resistant, and this type of paper requires good water absorption performance, clean and white, and transparent after immersion.

2.) Decorative paper, also known as wood grain paper. It has a base color or no base color, and is printed into various patterns of decorative paper. It is placed below the surface paper, mainly for decorative purposes. This layer requires the paper to have good covering power, impregnation, and printing performance.

3.)Cover paper, also known as titanium white paper, is generally placed under the decorative paper when manufacturing light colored decorative panels to prevent the bottom layer of phenolic resin from penetrating the surface. Its main function is to cover the color spots on the substrate surface. Therefore, good coverage is required. The above three types of paper are respectively impregnated with melamine resin.

4.)Bottom layer paper is the base material of decorative boards, which plays a mechanical role in the board. It is soaked in phenolic resin adhesive and dried. During production, several layers can be determined based on the purpose or thickness of the decorative board. When selecting this type of panel furniture, in addition to satisfying the color and texture, the appearance quality can also be distinguished from several aspects. Whether there are stains, scratches, indentations, pores, uniform color and luster, whether there are bubbles, and whether there are local paper tears or defects.

How many melamine faced boards ?

Melamine faced particle board

Melamine faced MDF

Melamine faced plywood

Melamine decorative board performance:

1. It can freely imitate various patterns with bright colors, and be used as veneers for various artificial boards . It has high hardness, wear resistance, and good heat resistance.

2. It has average resistance to chemicals and can resist the abrasion of general solvents such as acids, alkalis, oils, and alcohol.

3. The surface is smooth and easy to maintain and clean. Melamine board has excellent properties that cannot be combined with natural wood, so it is often used in indoor buildings and the decoration of various furniture and cabinets.

Melamine board is a wall decoration material. Common specifications: 2440mm × 1220mm, thickness 8mm -25mm.

Advantages and disadvantages:

The advantages of melamine faced board are: flat surface, less deformation due to the same coefficient of expansion on both sides of the board, bright color, more wear-resistant surface, corrosion resistance, and economic price.

The disadvantage of this type of board is that it is prone to edge cracking during edge sealing, and can only be sealed straight without any sharp edges.

Post time: Aug-28-2023