What is plywood?

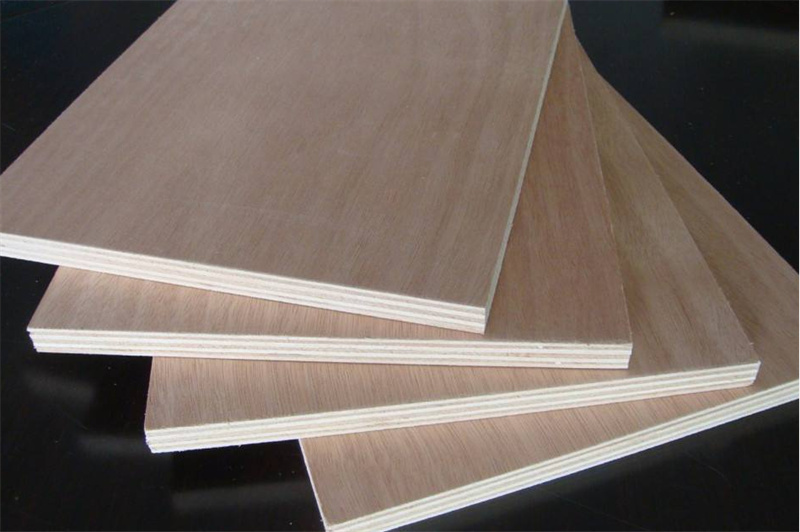

Decorative and furniture materials include plywood. It is composed of wooden veneerswith uniform or different thicknesses and connected together with adhesive of different strengths.

There are many types of plywood: such as hardwood plywood,softwood plywood, tropical plywood,aircraft plywood ,decorative plywood,flexible plywood ,marine plywood ,exterior plywood ,fancy plywood ,structual plywood .

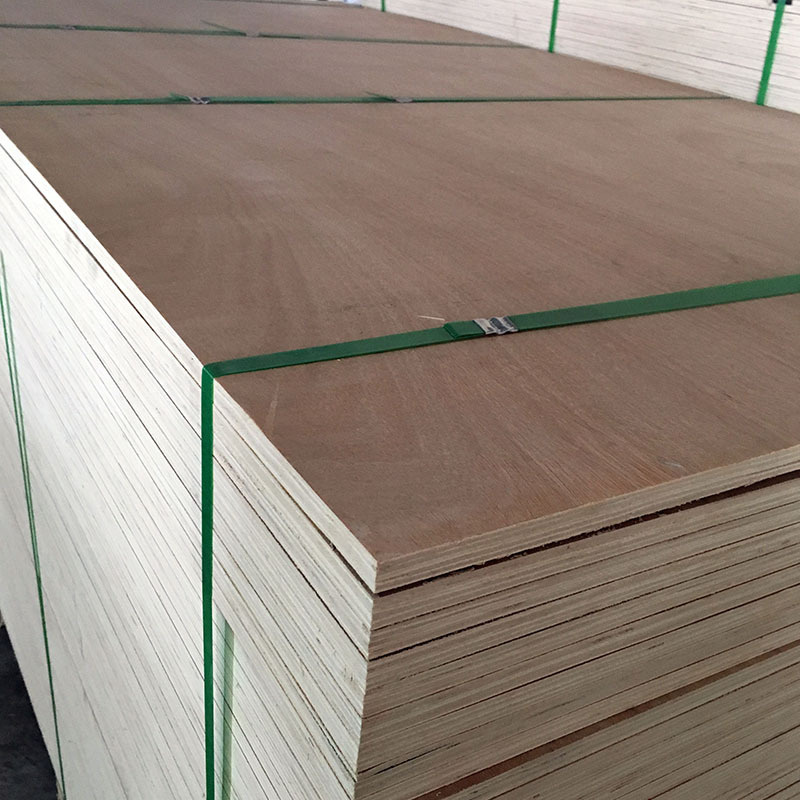

Plywood Size

4 feet by 8 feet is the standard size for plywood,also can be customized other sizes as customers’r requirements .

T&G plywood is often used in flooring applications. When the joint is not on the joist, this can prevent a board from moving up and down around its neighbors, forming a sturdy floor. The thickness of T&G plywood is usually between 13 and 25 millimeters (1/2 to 1 inch).

1.Commercial plywood

The commercial plywood mentioned here refers to the products made and sold by Linyi Wanhang Wood Industry . Our factory offers a variety of commercial plywood types, including Birch plywood, Combi plywood, Hardwood plywood, Pine plywood, and Poplar plywood. These types of plywood are suitable for various furniture-making applications, from cabinets and shelves to tables and chairs.

2.Softwood plywood

What is softwood plywood?

Softwood is sometimes referred to as spruce, pine, fir , .Although both cedar and Douglas fir can be used to make it. When using spruce construction, obvious particles are covered by a technology that makes plywood more effective in construction and formwork plywood, and as hard as concrete.

What are the applications of softwood plywood?

Many uses of high-quality, high-strength boards require the use of plywood. In this sense, quality refers to the resistance to warping, twisting, shrinkage, cracking, and fracture. Externally bonded plywood is suitable for outdoor use, but due to the impact of moisture on the strength of the wood, its performance is best when the moisture content is maintained within a relatively low range. The size and strength characteristics of plywood are not affected by sub zero temperature and can be used for certain unique applications.

Well, here are the applications of softwood plywood:

Used for ventilation panels.

Floors, walls, and roofs used for building construction.

Used in the manufacturing of mechanical and automotive components.

Used for construction work.

Used in the industry.

Used for packaging.

Used to set up a fence around an area.

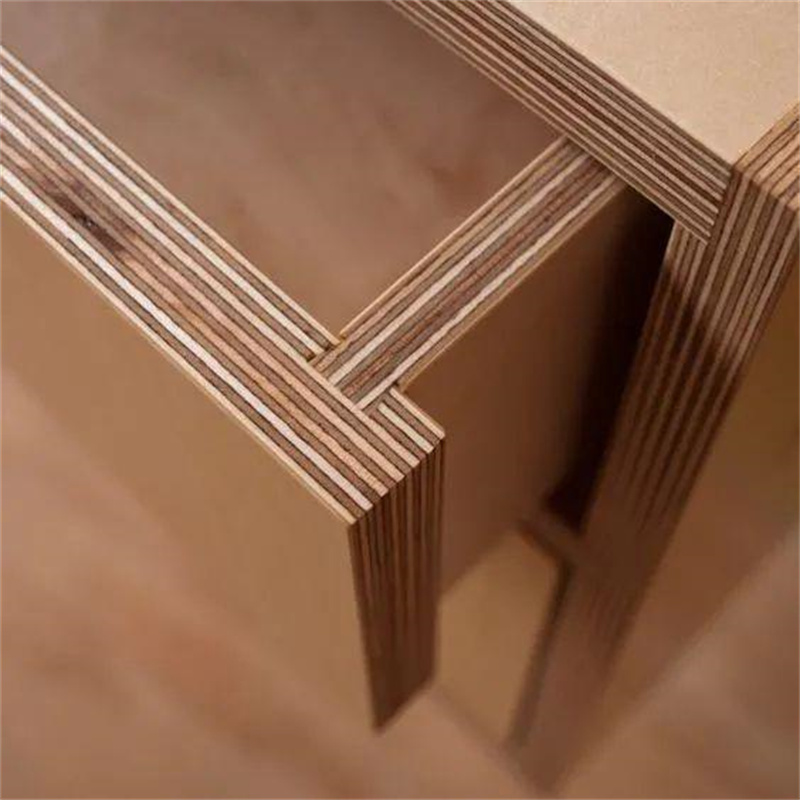

3.Hardwood Plywood

What is hardwood plywood?

Hardwood plywood can be identified by its hardness, surface hardness, non bending, and durability characteristics. It can be used to support heavy objects.

For demanding end uses, hardwood plywood made from dicotyledonous trees (oak, beech and Mahogany) is used. Excellent strength, stiffness, durability, and creep resistance are hallmarks of hardwood plywood. Due to its strong plane Shear strength and impact resistance, it performs well in heavy floor and wall structures.

What are the applications of hardwood plywood?

Common applications of hardwood plywood include:

Panels in concrete formwork systems

Floors, walls, and roofs of transportation vehicles

Container flooring

The floors of various buildings and factories are severely worn out

Scaffolding materials

Birch plywood is used as structural components in unique applications, such as windmill blades and insulation boxes for liquefied natural gas (LNG) transport ships

Hardwood plywood is strong and durable, ideal for furniture and decorations.such as birch plywood , oak plywood ,beech plywood ,mahogany plywood, maple plywood ,walnut plywood , poplar plywood –

4. Aircraft Plywood

Aircraft Plywood is a type of plywood made of thin veneer (usually birch wood) spun from uniform and high-strength wood, glued with phenolic resin adhesive. It has water resistance, climate resistance, and antibacterial properties. The plywood material is uniform, with good bonding performance, light bulk density, and high mechanical strength. It is used in the manufacturing of aircraft, gliders, and target aircraft.Aircraft plywood is among the highest-grade, most durable kind you can find.

5.Exterior Plywood

Exterior plywood has weather and water-resistant glue that holds each veneer together. When you create an exterior plywood, one of the biggest – and most important – concerns is how the wood will handle with wind, rain, and other climate conditions

6.Flexible Plywood

Flexible plywood bends without breaking, ideal for curved structures. It is commonly used for creating round structures like arches, domes, and barrels.

7. Marine Plywood

Marine plywood is defined as produced in accordance with the international standard of BS1088 Ocean Plywood, using phenolic adhesive, environmental protection grade E0/E1, boiling water for 72 hours without opening the adhesive. It is generally used in yachts, car boxes, ships, and outdoor wooden buildings, also known as “waterproof plywood” or “marine adhesive plywood”.

The product requires the use of good logs, sawn to the required length, and stripped of bark. Rotary cutting or planing, drying, repairing, then applying glue (cold pressing) and hot pressing, then repairing again after hot pressing, sawing edges, and sorting to form the finished product.

The core of the marine plywood is made of beech, willow eucalyptus, pine, birch, poplar, miscellaneous wood, combi core, etc; The face includes Bintangor, okoume, birch, etc. The face grade level is BB/CC, BB/BB, etc.

The conventional size of the Marine plywood is 1220 × 2440, 1220 × 2810, 1220 × 3035, 1220 × 3050, 1220 × 3660, with a thickness of 3-35mm.

8. Overlaid Plywood

Overlaid plywood, also known as decorative veneered plywood or fancy plywood ,which is made by slicing natural wood or technological wood into thin sheets of a certain thickness, adhering to the surface of the plywood, and then hot pressing. The materials used for overlaid plywood include stone, porcelain, metal, wood, and so on.

The plywood needs to be decorated to be more beautiful, and the common decoration techniques are sorted according to the price level as follows:

1) Melamine impregnated adhesive film paper veneer

2) Polymer coating

3) Baking paint

4) Solid wood veneer

Melamine impregnated paper veneer is commonly used to particleboard and plywood, and is the most common cabinet material in furniture. It can imitate various textures such as wood grain, stone grain, etc., and can enhance the surface wear resistance of the plywood through treatment such as fire prevention, wear resistance, and waterproof immersion.

Advantages:

The surface is flat, not easily deformed due to the same coefficient of expansion on both sides of the board, has bright colors, is more wear-resistant, corrosion-resistant, and has an economical price.

Good chemical resistance, able to resist the abrasion of general solvents such as acids, alkalis, oils, and alcohol. The surface is smooth, easy to maintain and clean.

9.Structural Plywood

Structural plywood is most suitable for building and construction purposes such as beams and hoardings. But the plywood can also be used for a crate, internal structures, boxes, and outdoor furniture. Some structural plywood is also used for wall and roof support.

CDX stands for “C-D Exposure 1 plywood”. C-D means that one side of the plywood is rated “C” grade and the other side is rated “D” grade. The letter “X” means the glue of the plywood is exterior glue. It is not a structural plywood .

You should know these things about plywood

Here are some things you should know about plywood before you buy it

1. Observe the surface of the plywood to see if there are cracks, wormholes, blisters, stains, and other defects on the surface. Some plywood is made by sticking two different grain veneers together, so when purchasing, it is necessary to check whether the joints of the plywood are tight and whether there are any unevenness.

2. Measure the actual thickness of plywood to see if it matches the nominal thickness at the time of sale by the merchant.

3. Pay attention to the bonding performance of plywood and choose boards with stable adhesive layer structure and no peeling phenomenon. When purchasing, you can use your hands to knock on various parts of the plywood. A crisp sound usually proves good quality, and a dull sound indicates poor bonding quality.

4. Observe whether the color and texture are consistent. As some plywood is made by adhesive bonding, it is necessary to observe whether its color and texture are consistent, and whether the color of the wood matches the color of the furniture paint. The color of the plywood to be purchased should be coordinated with the overall effect of the decoration.

5. Check if the workmanship of the plywood is fine. As the plywood is made of two single boards glued together, there will inevitably be both sides. The surface layer of plywood should have clear wood grain, smooth and flat front, and it is best not to have a rough and prickly feeling on the back, and it is best not to have nodes. If the plywood undergoes debonding, it not only affects construction but also causes pollution. Therefore, when selecting, you can gently tap the board with your hand. If a crisp sound is emitted, it indicates that the board is well adhered. If a thick sound is emitted, it indicates that the board undergoes debonding.

6. Choose environmentally friendly plywood and avoid purchasing plywood with obvious irritating odors

7.Which kind of plywood suit for you?

Your project and location will determine the kind of plywood you use. You can use marine plywood for boats, hardwood plywood for furniture, and bending plywood for round things.

Which plywood is the most durable?

8.Hardwood plywood is generally stronger than softwood plywood. Plywood is also strong because it has more layers and the wood grain runs in different directions.

9.Can you paint plywood?

Yes, you can paint plywood. Sand the surface, use a primer, and then use a brush or roller to put on the paint.

10.Can plywood hold up better than wood?

Plywood is less likely than wood to warp, crack, or split. However, it is not as strong when bent or hit, and nails don’t hold as well.

11.Ho long is plywood going to last?

How long plywood lasts depends on its type, quality, exposure, and maintenance. When installed and cared for correctly, plywood can last 10 to 20 years or more.

Post time: Jun-27-2023