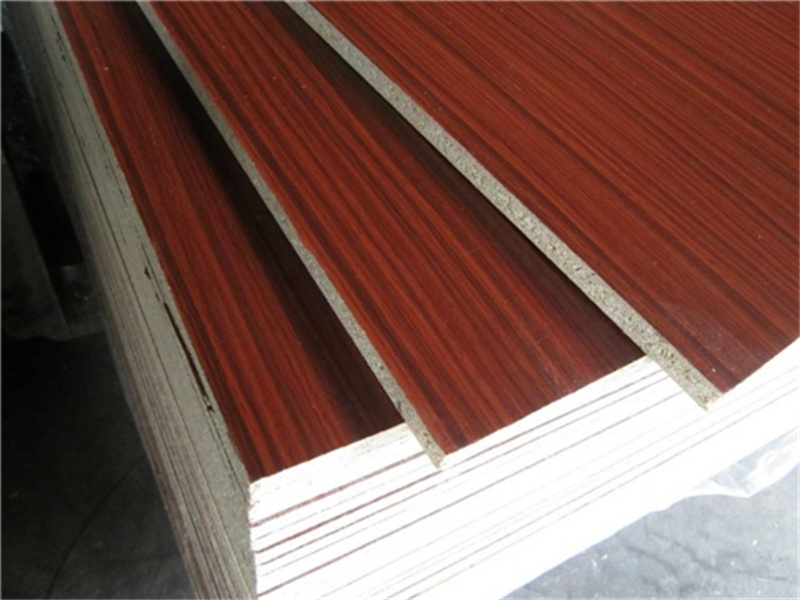

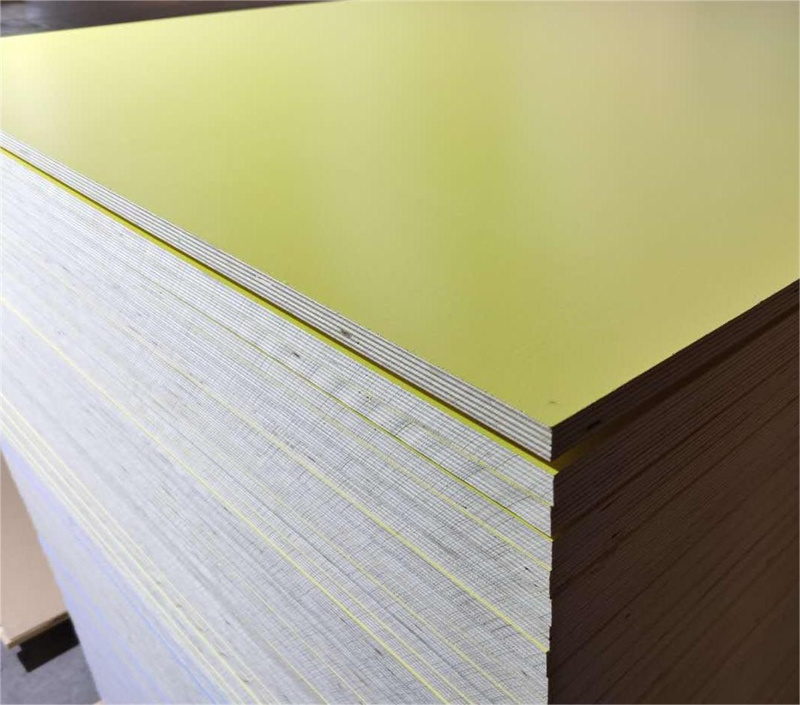

Melamine faced boards, whose base material is particle board, MDF , plywood,block board are bonded from the base material and the surface. The surface veneers are treated with fire prevention, abrasion resistance and waterproof soaking, their use effect is similar to that of composite wood flooring.

Melamine board is a synthetic board with melamine impregnated adhesive film paper veneer. Paper with different colors or textures is soaked in melamine resin adhesive, dried to a certain degree of curing, and then paved on the surface of particle board, moisture-proof board, medium density fiberboard, plywood, blockboard, multilayer board or other hard fiberboard, and then formed by hot pressing. In the production process, it is usually composed of several layers of paper, and the quantity depends on the purpose.

Soak the decorative paper in a melamine solution and then press it onto it through hot pressing. So, the moisture-proof board used for furniture is generally called melamine moisture-proof board. Melamine formaldehyde resin is a solution with extremely low formaldehyde content, which is environmentally friendly. This way of sticking it on not only does not cause secondary pollution, but also reduces the release of the substrate inside. This treatment method has been recognized by many people and is mostly done in this way.

Composition

“Melamine” is one of the resin adhesives used to manufacture this kind of board. Paper with different colors or textures is soaked in the resin, dried to a certain degree of curing, and then paved on the surface of particle board, medium density fiberboard or hard fiberboard. The decorative board is made by hot pressing. The specification name is melamine impregnated adhesive film paper facing wood-based panel, Calling its melamine board is actually a part of its decorative composition. It is generally composed of surface paper, decorative paper, covering paper, and bottom paper.

① Surface paper is placed on the top layer of the decorative board to protect the decorative paper, making the surface of the board highly transparent after heating and pressure. The board surface is hard and wear-resistant, and this type of paper requires good water absorption performance, clean and white, and transparent after immersion.

② Decorative paper, also known as wood grain paper, is an important component of decorative boards. It has a base color or no base color, and is printed into various patterns of decorative paper. It is placed below the surface paper, mainly for decorative purposes. This layer requires the paper to have good covering power, impregnation, and printing performance.

③ Cover paper, also known as titanium white paper, is generally placed under the decorative paper when manufacturing light colored decorative panels to prevent the bottom layer of phenolic resin from penetrating the surface. Its main function is to cover the color spots on the substrate surface. Therefore, good coverage is required. The above three types of paper are respectively impregnated with melamine resin.

④ Bottom layer paper is the base material of decorative boards, which plays a mechanical role in the board. It is soaked in phenolic resin adhesive and dried. During production, several layers can be determined based on the purpose or thickness of the decorative board.

Post time: May-29-2023