The key to the durability of any building lies in having a solid foundation and the use of reliable frames, so the foundation of the building must be impeccable. Birch plywood is an economical, sturdy, and durable material commonly used for various vertical and horizontal structural formwork, including floors, walls, columns, and scaffolding. The assembled formwork composed of metal and plywood ensures the maximum geometric proportion of future buildings.

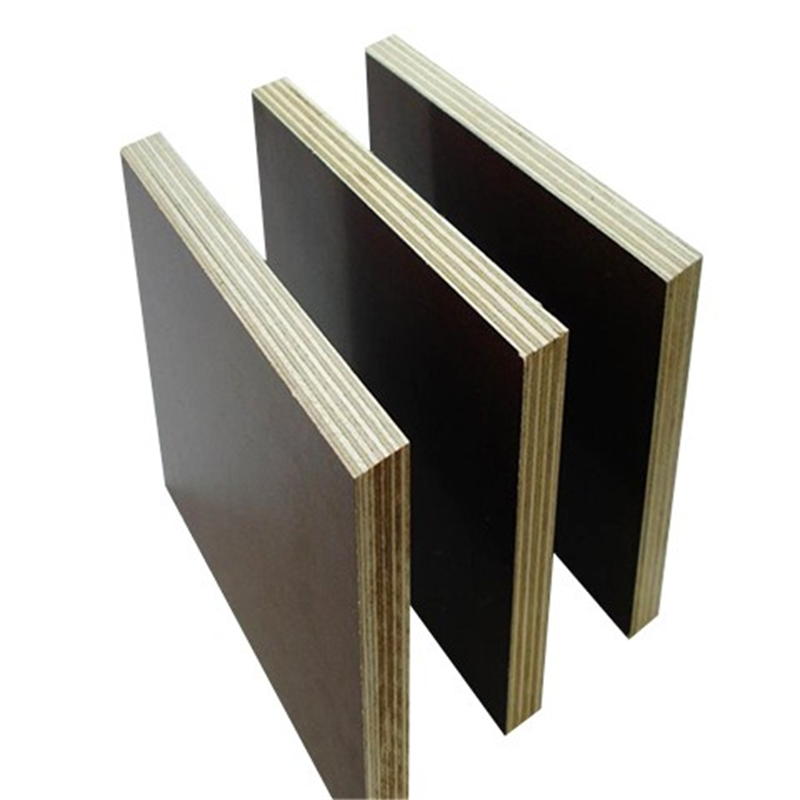

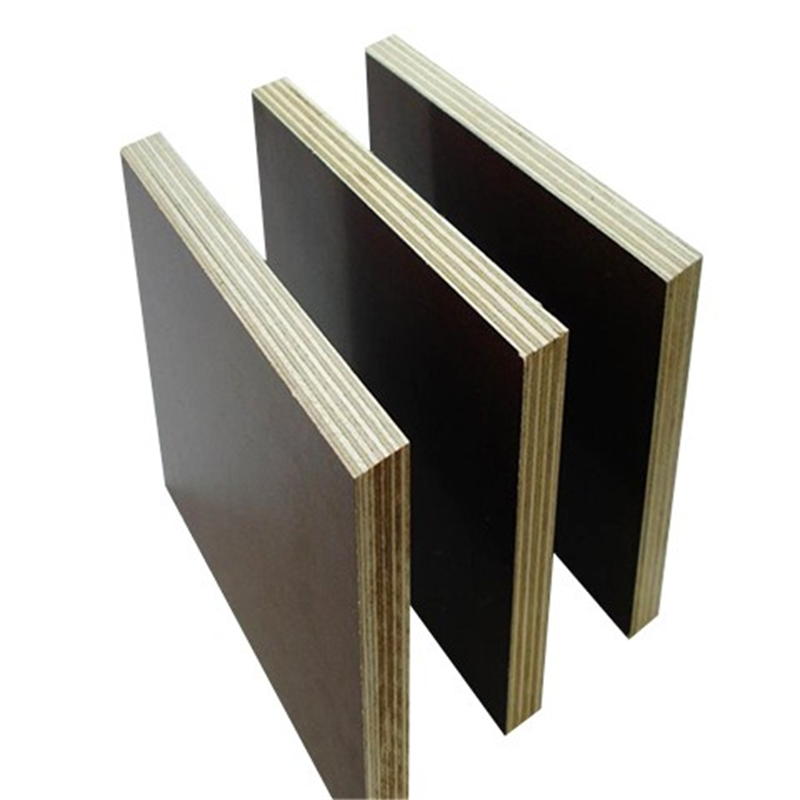

The primary choice for building formwork is laminated plywood.

The waterproof film on the surface of laminated plywood prevents deformation caused by concrete and other corrosive substances.

The end of the board has undergone special moisture-proof treatment.

The smooth surface of plywood perfectly separates it from hardened concrete, without causing defects or inclusions.

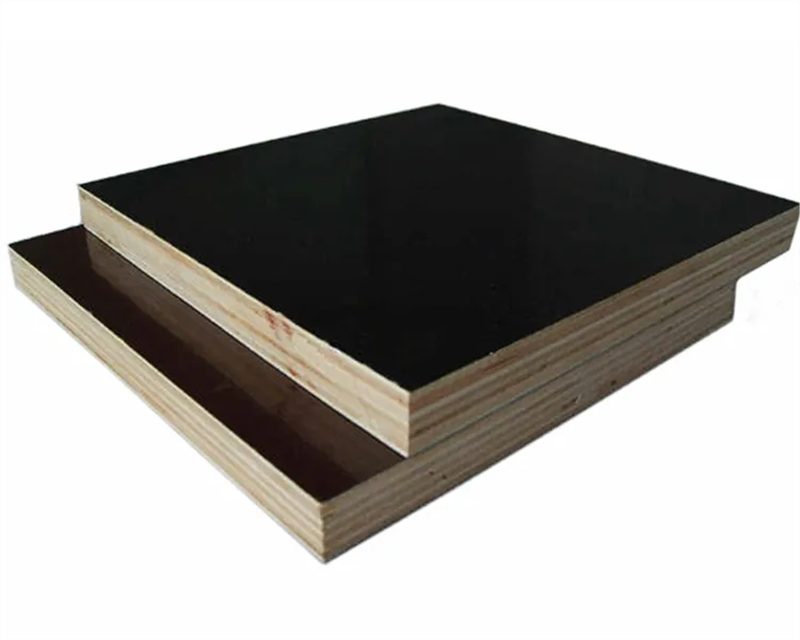

A set of construction formwork plywood can be used for multiple concrete pouring cycles.

Formwork shutter Plywood can be processed and adjusted directly on the construction site using woodworking tools.

The best performance combination makes it perfectly capable of handling various floor weights.

During the construction of small buildings, you do not need professional equipment to manually move the plywood, as the material itself is lightweight.

Plywood can be applied to all types of formwork. The most widely used formwork is for floors, walls, and columns. For wall formwork, either use formwork cards or use panels designed according to the project type. Regarding the selection of floor slabs, it is more commonly used for beam column formwork, where plywood is laid on the surface and fixed with nails or self tapping nails. But there is also a special type of shuttering : for example, specialized customized shutterings for bridge or subway construction processes.

One architectural style is a radial structure characterized by rounded corners and smooth lines.In these projects, beam column construction formwork systems are often used.

When building geometrically complex buildings, it is usually most convenient to use flexible plywood. This specialized plywood saves on-site working hours and labor, and reduces the demand for specific equipment and systems. In addition, flexible plywood is easy to transport and can be perfectly restored to its original state after stripping.

We suggest using a building formwork plywood with a specification of 1220 * 2440mm laminated film of 220 grams per square meter, which has a high turnover rate and maximizes the protection of the plywood front.

The category of wood used to make plywood. Each category has its own advantages, which can affect product characteristics. Birch wood is a high-density material, and with special veneers, plywood will become very durable. In laminates, we recommend choosing building plywood with phenolic resin film, which perfectly interacts with concrete and does not produce adhesion.

Manufacturers should have a sense of responsibility not only ensure the quality of their products, but also ensure the quality of raw materials and after-sales service.

Post time: Jun-27-2023