What is a decorative veneer plywood ?

Decorative panel is a type of artificial board used for decoration, also known as decorative veneer plywood. It is made by cutting wood veneer, plastic, paper and other materials into thin sheets, with a thickness of 1mm .The thin sheets are then used as veneers to stick to the base boards such as plywood, fiberboard, and particle board. Simply , decorative plywood=veneer+base board.

The purpose of decorative plywood

Veneer treatment can improve the physical and mechanical properties of the substrate, making the surface of the substrate wear-resistant, heat-resistant, water-resistant, and corrosion-resistant, while improving and enhancing the strength and dimensional stability of the material. Kitchen furniture is required to have properties such as moisture resistance, waterproofing, and corrosion resistance. The achievement of these properties not only depends on the performance of the substrate itself, but more importantly, is influenced by factors such as veneer materials, veneer processes, and veneered methods.

Veneer treatment can improve the surface decoration effect of the substrate, simplify the furniture production process, eliminate traditional mortise structures and heavy coating operations, and lay the foundation for achieving standardization, serialization, and continuity in modern furniture production.

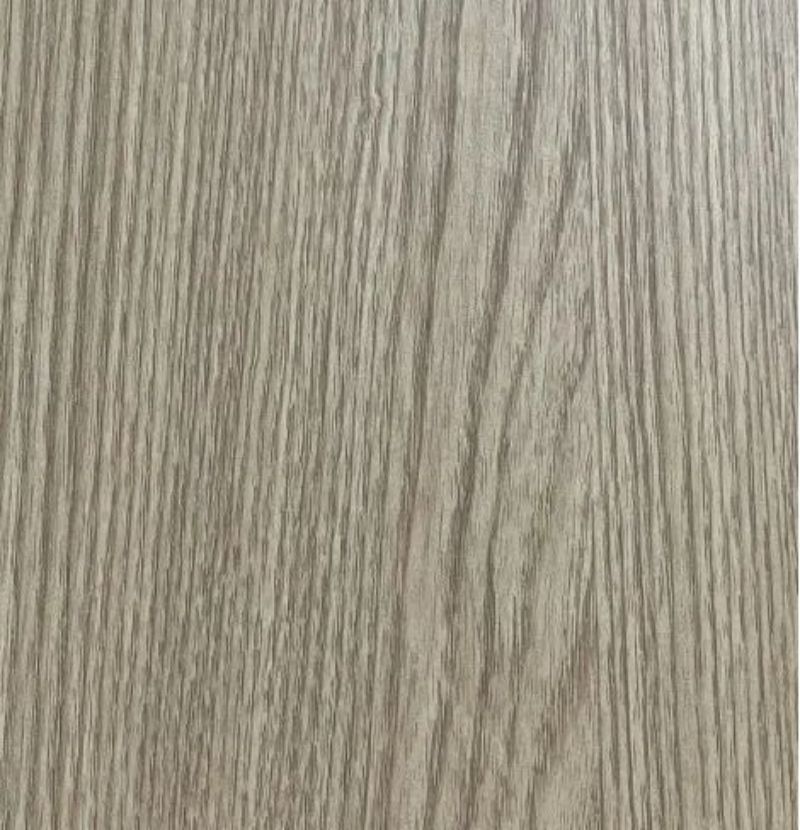

Wood grain decorative plywood

Processing wood into thin wooden veneers ,this type not only preserves the beauty texture of the wood but also retains its breathable function, making it the highest quality material in the veneer.

It can improve the physical properties of the substrate, making it more wear-resistant, heat-resistant, water-resistant, corrosion-resistant, etc., improving the stability of the material’s performance, and better preventing material cracking, deformation, and other qualitative changes; Enhance the aesthetic effect, which can cover natural and processing defects on the material surface;

Solid color decorative plywood

The names of decorative panels come in a variety of ways, and the difference lies in the differences between the substrate and finish. Different substrates and finishes determine the properties of the board, and different properties of the board adapt to different spatial conditions and aesthetics.

Classification of decorative plywood

According to the different raw materials of the decoration, common decorations on the market can be divided into wood veneer, plastic veneer, paper veneer, etc.

Wood veneer

Wood veneer is made by using raw wood material to plane and cut thin slices, and undergoing multiple processes such as high-temperature painting. The wood used is different, and the patterns are also different.

Common wood veneers include poplar, birch, Okoume wood, bintangtor wood, teak, walnut, maple, ash, etc. Because it is directly made of natural wood, the wood veneer has the advantages of being authentic, natural, non cracking, and non deformable; The disadvantage is that the price is relatively high, the wood grain style is limited, and the maintenance is also quite complex, and it is not suitable for damp environments.

Plastic veneer

Common plastic finishes include a softer polyvinyl chloride film, also known as PVC, which is one of the most commonly used finishes in cabinet customization.In terms of pattern texture, PVC can shape various styles and imitate various wood patterns. It can use a variety of colors and is also cheap.

Paper veneer

There are many types of paper veneers, mainly including pre coated decorative paper, low-pressure thin paper short cycle veneers, high-pressure amino resin veneers, etc. The most popular one in the market is melamine paper veneer.

Soak the patterned paper in the adhesive, take it out to dry, and the paper will have patterns resembling solid wood paint, so melamine decorative panels are also known as paintless panels.

Melamine plywood has the characteristics of moisture resistance ,and can be used in damp environments such as kitchens and balconies.

In addition to the common decorative plywood mentioned above, there are also various types of decorative plywood such as bamboo veneer plywood.

If there are no special processes and environmental requirements, the above three types of finishes plywood can fully meet the functional and aesthetic requirements of home decoration panels.

Edge sealing of decorative plywood

The most trouble some issue with artificial boards is the formaldehyde emmison in the substrate. Whether the board is environmentally friendly and safe is not only related to the formaldehyde content of the substrate adhesive, but also to whether the surface wrapping is tight. The key to determining the amount of formaldehyde released is whether the adhesive used for the substrate and the sealing edge are good or not.

So when choosing decorative plywood, it is necessary to check the grade of adhesive used for the plywood, whether they comply with national standards, and also carefully check whether the edge sealing quality is qualified.

Good edge sealing not only protects the board, but also controls the release of free formaldehyde from the source through seamless processing, ensuring the air quality of the home space; On the other hand, special edge banding can even enhance the overall design effect and aesthetics of the furniture.

Post time: Aug-22-2023